High TG Value: The Cornerstone of PCB Thermal Reliability from a Professional Perspective

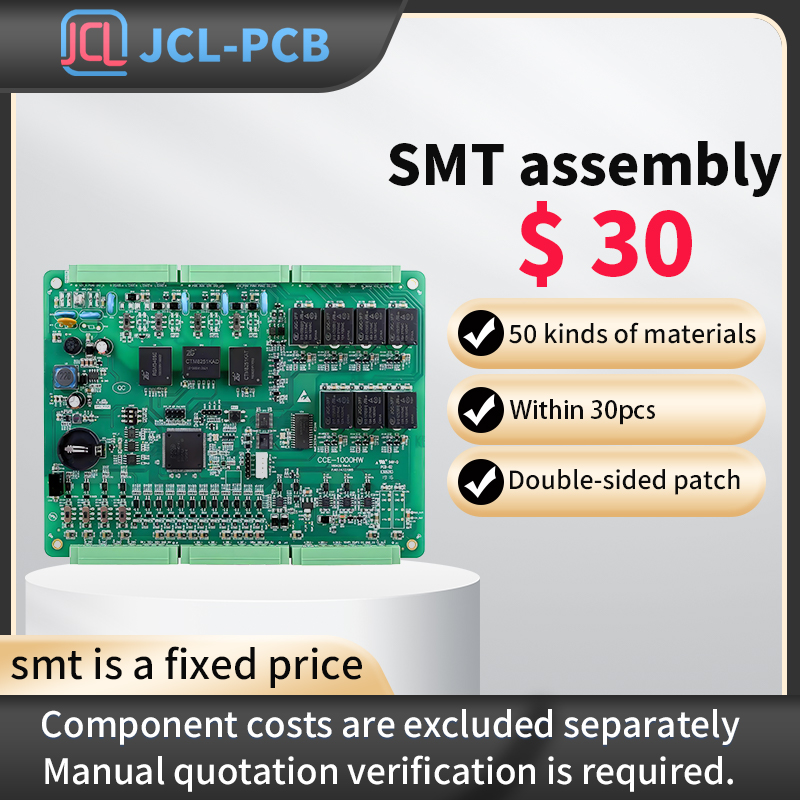

In high-speed design, power electronics, and harsh environment applications, the glass transition temperature (Tg) of the substrate material is no longer a secondary parameter, but a core indicator that determines product reliability and performance limits. Understanding the true value of high Tg is the key for engineers to achieve robust designs. Technical Definition and Physical Significance of Tg Tg (Glass Transition Temperature) refers to the critical temperature point at which the base material transforms from a rigid "glassy state" to a flexible "rubbery state". Beyond the Tg level, the materialâs mechanical strength, dimensional stability, and coefficient of thermal expansion (CTE) will undergo nonlinear abrupt changes. Essentially, a higher Tg value means that the materialâs operational "rigid range" is expanded. Three Engineering-Grade Advantages of High-Tg Substrates 1. Excellent Thermomechanical Stability During multiple lead-free reflow soldering processes (where peak temperatures often exceed 260°C), low-Tg substrates (e.g., Tg140) may enter or approach the transition zone, resulting in board warpage, laminate microcracks, or a sharp increase in solder joint stress. High-Tg substrates (e.g., Tg170/180) can maintain a glassy state at such temperatures, delivering the following benefits: Lower Z-axis coefficient of thermal expansion (CTE): Reduces the risk of thermal stress-induced fracture in the copper barrels of plated through-holes (PTH). Suppression of board warpage: Provides a flat soldering platform for high-density BGA and fine-pitch components, improving first-pass yield rates. 2. Guaranteed Long-Term Reliability and Signal Integrity During equipment operation, continuous heat generation from chips and power devices creates a high-temperature field inside the PCB. The advantages of high-Tg materials include: Reduced thermal aging rate: The degradation of the materialâs physical and electrical properties is slower in high-temperature operating environments. Stable dielectric constant (Dk/Df) retention: This is critical for impedance control and signal loss reduction in high-speed digital circuits and radio frequency (RF) circuits. Enhanced CAF resistance: High-Tg, high-performance material systems typically exhibit superior resistance to ion migration, preventing insulation failure caused by humidity, heat, and electric fields. 3. Empowering Advanced Designs and Complex Applications High Tg is a prerequisite rather than an optional upgrade for the following applications: High-end HDI and any-layer interconnection: Provides a dimensional foundation for multiple lamination and laser drilling processes. Thick-copper multilayer PCBs: Withstands high-current heating and intense thermal stress. Embedded component packaging: Ensures structural stability of cavities housing embedded components during high-temperature manufacturing processes. Automotive engine compartment controls, industrial motor drives, and base station power amplifiers: These fields require devices to function properly under long-term high-temperature conditions (e.g., 125°C). Selection Recommendations: When Is High Tg a Must-Specify Requirement? A concise decision-making framework is as follows: if your design involves multiple reflow soldering cycles, operates in high-temperature environments (>85°C), features complex multilayer structures (â¥8 layers), or falls into high-reliability categories (automotive-grade, medical-grade, industrial-grade), selecting medium-to-high Tg (Tg150+) or ultra-high Tg (Tg170+) substrates should be the default choice. It represents a strategic investment in manufacturing costs to avoid substantial field failure risks. Join JCL â Enjoy Complimentary Upgrade to High-Tg Substrates

Post a Comment